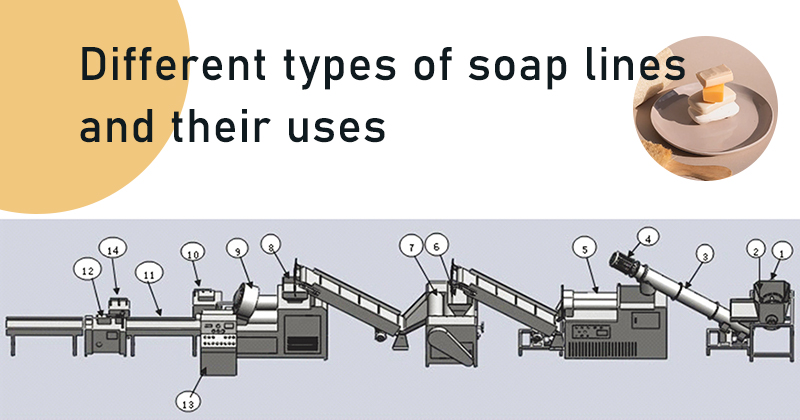

Soap is one of the indispensable cleaning products in our daily lives, and soap lines are one of the key tools used in the production of soap. Different types of soap lines are designed to meet a variety of different production needs, and they all have important roles to play in different applications. In this article, we will introduce the different types of soap lines and their uses in different applications.

- Continuous Soap Lines:

Purpose: Continuous soap lines are typically used for large-scale soap production, such as industrial grade soap. This type of soap line is able to produce large quantities of soap efficiently and is suitable for situations where there is a high demand in the market.

FEATURES: Continuous soap lines utilize a continuous process that allows for ongoing soap production, reducing production downtime and increasing efficiency. - Semi-continuous soap lines:

Purpose: The semi-continuous soap line is often used for soap manufacturing on a medium production scale and is suitable for situations where soap needs to be cut quickly.

FEATURES: It combines the characteristics of continuous production and batch production to maintain a certain production speed while also allowing soap blocks to be cut and adjusted as needed. - Batch soap line:

Purpose: The Batch Soap Line is typically used for small-scale or specialty types of soap production, such as handmade soap or soap with special ingredients.

CHARACTERISTICS: This type of soap line allows the producer more flexibility to control the production process by adding different ingredients and colors to meet the diverse needs of the market. - Cold soap lines:

Purpose: Cold Process Soap Lines are used for the production of cold process soaps, which are often enriched with natural ingredients such as vegetable oils and essential oils.

Characteristics: The relatively gentle process of cold process soap production preserves the beneficial ingredients in the raw materials, making it suitable for markets seeking natural and organic soaps. - Hot Soap Lines:

Purpose: Hot soap lines are primarily used in the production of industrial-grade soaps, such as laundry or cleaning soaps.

Characteristics: The hot soap production process requires high temperatures and is able to dissolve raw materials quickly, making it suitable for mass production where high yields are required.

In summary, there are many different types and uses for soap lines, which can be selected based on the scale of production, type of product and market demand. Whether it is large-scale industrial production or small-scale artisanal production, soap lines play a key role in ensuring high quality soap production. As the demand for natural and organic products continues to grow, so does the use of cold process soap lines, reflecting the constant innovation and evolution of soap production. We hope this information helps you better understand the different types and uses of soap lines.