Bar Soap Machine

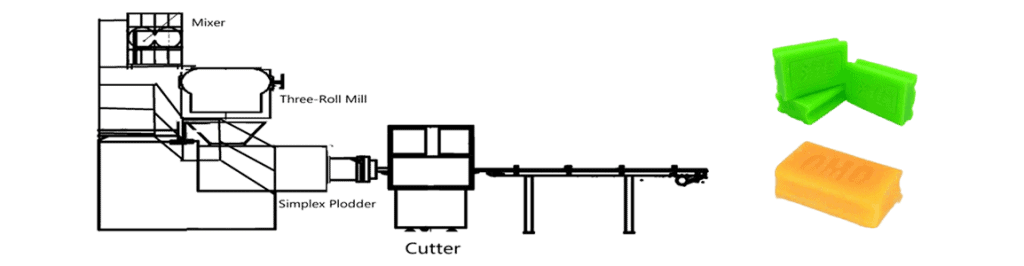

The standard Small Soap Making Line, is composed by the Mixers, able to mix soap noodles with perfume and colors per batch, the Plodders/Extruders to refine and extrude the soap bar, and the Soap Presses.

The SOAP NOODLES, perfume and colors are mixed inside the Soap Mixer for a variable time from 5 to 10 minutes, depending from the coloring intensity. After the mixing, the soap base is ready to be refined and extruded by means of the Soap Extruder (also called Soap Plodder); the extruded long soap bar is cut by hand, then the cut soap bars are ready to be stamped using one of our Soap Presses.

We can studied customized solutions as per Customers requests also.

100KG/H Toilet & Laundry Soap Semi-Auto Finishing Line

This line can make TOILET&LAUNDRY SOAP, it includes below machines

| Item | Machine Name | Qty |

|---|---|---|

| 1 | ST-M 50 Mixer | 1 Pc |

| 2 | ST-RM150 Three Roll Mill | 1 Pc |

| 3 | ST-SP 100 Plodder | 1 Pc |

| 4 | ST-MC 50 Stamper with one mold | 1 Set |

| 5 | ST-MC 120 Cutter with one mold | 1 Pc |

What you need to PREPARE

- Water: 0.5-1 cubic circulated water (not consumed)

- Electric: 30-40Kw/H, 380V, 50Hz;

- Workshop Space: L 10m * W 8m * H 4m, the size of the material storage area depends on the customer's own needs

- Labors: 2-3 Persons/Shift.

- Raw Materials of Soap.

100KG/H Laundry Soap Auto Finishing Line

This line can make LAUNDRY SOAP ONLY, it includes below machines

| Item | Machine Name | Qty |

|---|---|---|

| 1 | ST-M 50 Mixer | 1 Pc |

| 2 | ST-RM150 Three Roll Mill | 1 Pc |

| 3 | ST-SP 100 Plodder | 1 Pc |

| 4 | ST-AC 250 Cutter with one mold | 1 Set |

| 5 | Conveyor | 1 Set |

What you need to PREPARE

- Water: 0.5-1 cubic circulated water (not consumed)

- Electric: 30-40Kw/H, 380V, 50Hz;

- Workshop Space: L 10m * W 8m * H 4m, the size of the material storage area depends on the customer's own needs

- Labors: 2-3 Persons/Shift.

- Raw Materials of Soap.

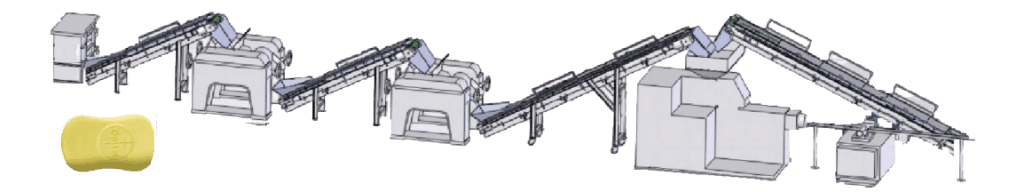

100-300KG/H Toilet Soap Auto Finishing Line

This line can make TOILET SOAP ONLY, it includes below machines:

| Item | Machine Name | Qty |

|---|---|---|

| 1 | ST-M 500 Mixer | 1 Pc |

| 2 | ST-RM 150 Miller | 2 Pc |

| 3 | ST-DP 100 Duplex Plodder | 1 Pc |

| 4 | ST-AS 100 Stamper with one mold | 1 Pc |

| 5 | Conveyors | 3 Pc |

| 6 | ST-C12HP Cooling Water Machine | 1 Pc |

| 7 | ST-R6HP Refrigerator | 1 Pc |

| 8 | Vacuum Pump | 1 Pc |

What you need to PREPARE

- Water: 0.5-1 cubic circulated water (not consumed)

- Electric: 40-50Kw/H, 380V, 50Hz;

- Workshop Space: L 22m * W 10m * H 5m, the size of the material storage area depends on the customer's own needs

- Labors: 2-3 Persons/Shift.

- Raw Materials of Soap.